- Homepage

- Brand

- Letterpress

- Material

- Aluminum (4)

- Brass (68)

- Copper (46)

- Foundry Type Metal (12)

- Lead (160)

- Metal (207)

- Metal & Wood (9)

- Metal On Wood (4)

- Paper (119)

- Plastic (8)

- Rubber (7)

- Steel (23)

- Stone (3)

- Stone Ground Rubber (14)

- Synthetic Resin (28)

- Type Founders Metal (5)

- Uncoated Paper (4)

- Wood (545)

- Wood Metal (7)

- Wood, Metal (4)

- Other (3646)

- Model

- Brother Gt 541 (7)

- Capsure (9)

- Dx4 (19)

- Efi Es-2000 I1 Pro (8)

- Es-1000 (9)

- Es-2000 (47)

- Gp1601n (27)

- Gp6102a (8)

- Kelsey 3x5 (11)

- Kelsey Rollers 5x8 (10)

- Metal Type (38)

- Oem (8)

- Original (35)

- Print Block (59)

- Printer Reset Kit (13)

- Printers Cut (73)

- Pro (8)

- Stylus Pro 3880 (10)

- X-rite I1 Pro 2 (22)

- 331 (8)

- Other (4494)

- Sku

- Type

- Book (4)

- Case / Storage (6)

- Color Book (3)

- Color Bridge Coated (5)

- Color Matcher (6)

- Compatible (5)

- Cotton Passport (4)

- Foundry Type Block (23)

- Ink Cartridge (5)

- Inkjet Printer (3)

- Letterpress (3)

- Letterpress Block (126)

- Letterpress Type (594)

- Metal Stamps (6)

- Pantone Guide (5)

- Pantone Metallics (8)

- Pantone Solid (4)

- Print Head Damper (4)

- Printing Block (286)

- Solvent (11)

- Other (3812)

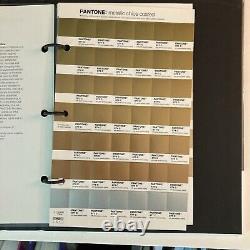

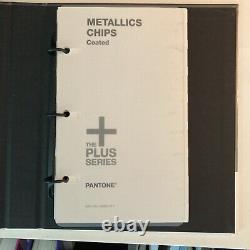

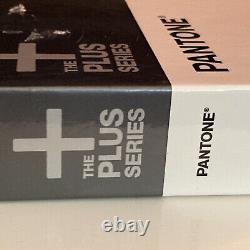

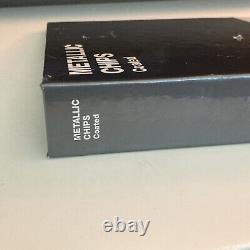

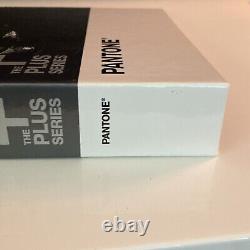

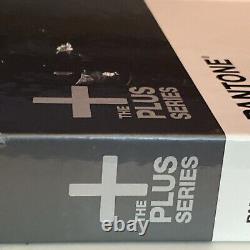

Pantone Plus Series Metallics Chips Coated book Reference For Printing Metallic

This Pantone Plus Series Metallics Chips Coated book is the perfect reference for anyone in the printing industry. With a wide range of metallic colors from PANTONE, this book is a must-have for those looking to add a touch of shine to their designs. The book contains no indication of previous use and is in excellent condition. The brand, PANTONE, is known for its quality and reliability in the printing industry, and this book is no exception. The book features Pantone Metallics, a type of material that is made from metal and has a unique shine. It was manufactured in the United States and has not been modified in any way. This custom bundle does not come with any additional materials. Echnical Notes, Pantone Metallics "classic". Mixing metallic inks with conventional printing inks is a process that requires special attention. To obtain optimal results, it is advisable to mix shortly before printing. To guarantee the expected results, it is important to have a homogeneous mixture. Metallic colors have a higher opacity than conventional printing inks.

For optimal results, it is worth evaluating the printing sequence. In some cases it may be necessary to remove the metallic ink to avoid screening problems. Small print areas or halftones may require an additional solid bar outside the print area to ensure proper ink flow. If a solid area and halftones are printed on the same sheet, it is advisable to print them separately for maximum intensity and definition. Metallic colors usually have several layers to increase their durability.

All layers must be tested in advance to ensure compatibility. The type of coating used can affect the luster of the metallic print.

For best results, it is recommended that you use quality coated paper. Loss of color, shine, and metallic luster may be observed in materials that do not have good absorbency properties.

The following factors can influence the final appearance of the product. Use of offset color guides. Thickness of ink films (density).

Design and control of printing copper. Paper variations in absorption, quality and texture. Accuracy of color combinations inks Lighting.

This color book is in excellent used condition and there is no page missing, few chips takes out but you have all colors.